Have you ever wondered how steel is bent into different shapes? This type of metal is known for its strength, lending itself to use in a wide range of industries. From manufacturing to construction, steel is one of the most widely used metals in the world. Here’s a guide to six steel bending techniques commonly used today.

-

Free Bending

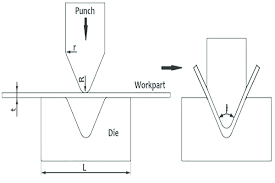

Free bending, also known as air bending, involves pressing metal down into a die. The clever thing about this technique is that different angles can be created by adjusting how far the steel is pressed down.

2. Bottom Bending

Bottom bending and free bending use a similar technique. However, the difference between them is that with bottom bending, the material is always pressed right to the base of the die to get the exact shape.

3. Rolling

Probably one of the most well-known ways to bend steel is through rolling. This is where metal is pushed through rollers to create the desired shape, and it can be done both on a small scale as well as for industrial applications. It is widely used to create cylindrical shapes from steel.

-

Press Break

These are large pieces of industrial equipment that are used to bend sheet metals, again using a punch-and-die method. However, their large size can be a limiting factor.

An alternative to press breaks is Euromac bending machines. More information can be found about these at /www.cotswold-machinery-sales.co.uk/euromac-bending-machines/horizontal-bending-machines.

5. Folding

As the name suggests, this is a technique used to bend metal along a simple fold, using a straight line. According to The Engineer, folding is the ideal solution to bending thicker metals, thanks to its high degree of accuracy.

6. IncrementalThis is where metal is bent in small stages or increments. This is a cost-effective method as no dies are required to achieve the desired shape.

When working with metals such as steel, effective bending techniques are essential. Thankfully, with the many bending techniques available, there are plenty of options for shaping metals for a variety of different needs.